CONTROL OF CASTING PRODUCTION PROCESS

1. SAND ANALYSIS

There is a line for testing the quality of foundry sand in the laboratory.

– Cohesion metre – testing the strength of the sand mixture with

pressure

– Electronic permeameter – determining the permeability of the sand mixture

– Dryer with infrared rays - determining humidity on the sample of a foundry

sand mixture

– Rammer – compressing samples of sand mixtures

– An instrument for determining the strength of the cores or moulds

2. ANALYSIS OF CHEMICAL

COMPOSITION

Analysis of the chemical composition of materials is performed by a

high-quality spectroscope that operates on the principle of optical emission

spectrometry – LECO GDS 500A.

Possibility of the quantitative analysis of the following samples:

– low-alloy steels

– cast iron

– Al-alloys

– Cu- alloys

– bronze, etc.

3. VISUAL EXAMINATION OF

CASTINGS

After a casting is cleaned, the first control examination is performed in

order to prevent or reduce any errors.

After this, the castings are shot blasted and each piece is visually inspected

in detail. If the quality of the casting meets standards, it is packaged and

taken to the warehouse.

If irregularities are spotted during the inspection, the casting is sent for

reworking and undergoes another inspection after this.

4. CONTROL OF CASTING

DIMENSIONS

The dimensions of the castings are measured with the FARO measuring arm.

Measurements are performed according to the drafts made by the buyer, with an

accuracy of up to ±0,005mm.

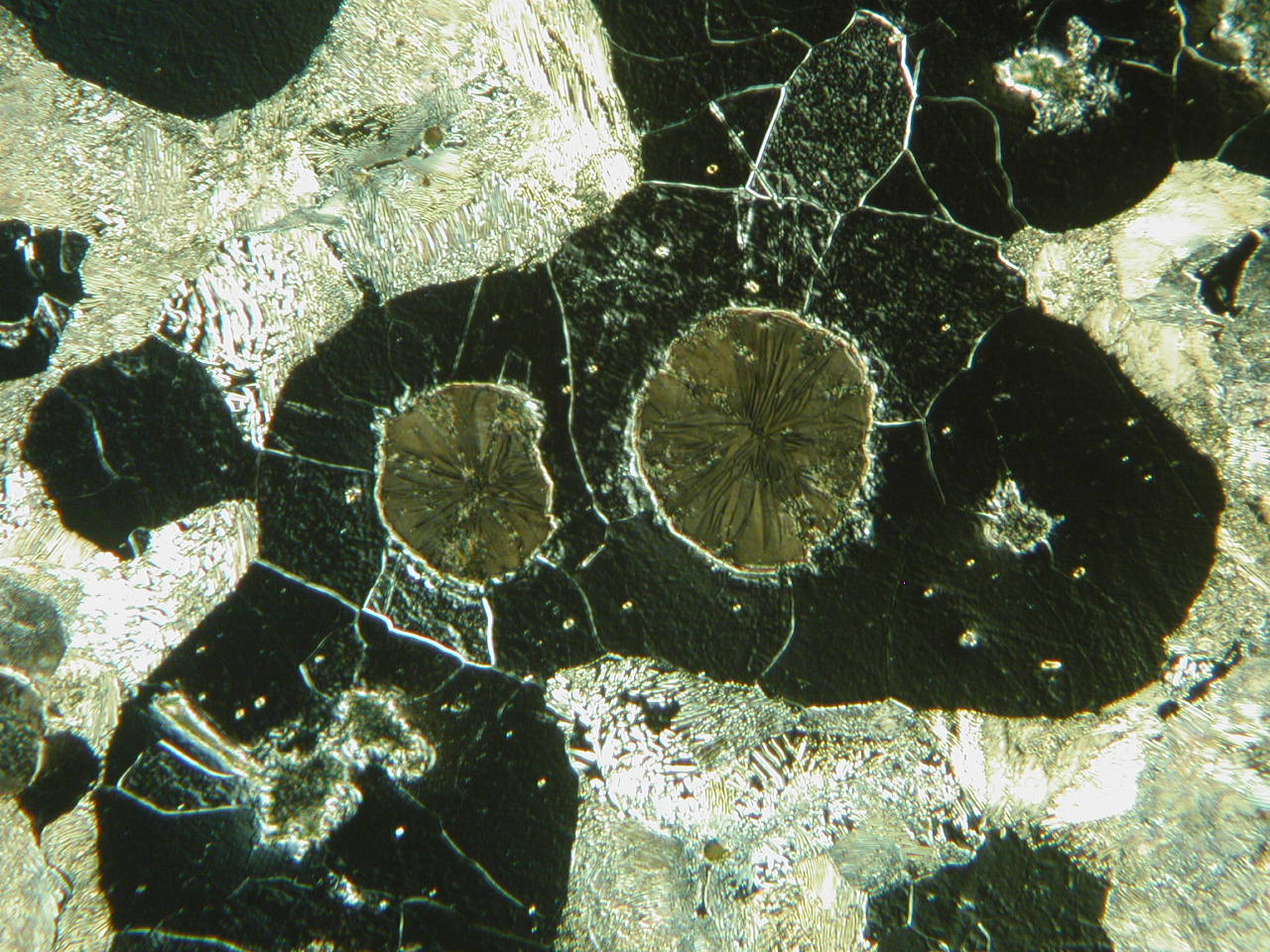

5. MICROSTRUCTURE CONTROL

Testing the microstructure, with the preparation of samples by sanding

(from coarse to fine), polishing and etching.

Microscopic examinations are performed with the aim of determining

microstructure, the content of certain structures (microconstituents), grain

size, grain orientation, size and distribution of inclusions etc.

The microstructure is determined with etched samples and the aid of the optical

digital microscope, magnification 50x, 100x, 150x and 200x. Image analysis is

performed automatically by the software of the LECO company.

6. CONTROL OF MECHANICAL

PROPERTIES

Testing hardness on a hardness meter with the Brinell indentation hardness

test. Indentation measurement – Brinell Video System HBVS 100

7. TESTING METAL STRENGTH

Through static tensile testing on the SHIMADZU AG-X testing machine, it is

possible to determine the basic properties of a material such as:

– Ultimate tensile strength – Rm

– Yield - Rp02

– Elongation – A

– Contraction – Z

The computer-controlled testing machine SHIMADZU AG-X conducts tests and

records their results in electronic form, as well as producing a Hooke diagram

on the basis of the results obtained through material testing.

The testing machine is equipped with a video extensometer and meets

all the norms of EN-ISO-6892.